Mechanical Engineering

Challenges for extraction systems in mechanical engineering

In mechanical engineering, a wide variety of production processes such as welding, grinding, sawing, soldering and drilling generate substances that are harmful to health. For the safety of employees, occupational safety requires the filtering of these fumes, dusts, chips and gases. Changing and difficult to reach workplaces or large workpieces can make effective extraction difficult. In addition to selective extraction using extraction arms or hoods, we therefore also offer complete, customized hall extraction systems including pipe systems.

PROCESSES

- Flame cutting, plasma cutting, spot/seam welding (MIG/MAG, TIG), tacking

- Laser cutting, laser drilling, laser ablation, laser welding, laser marking

- Deburring, ablation, brushing, plastering, grinding, polishing

- Cutting, sawing, flexing, cutting

MEDIA

- Burning or explosive dusts

- Metal dusts of aluminum, magnesium, steel, titanium

- Wet or sticky dusts

- Leather, rubber and plastic abrasion

- Fibers, lint, textile dusts

- Chips

AREAS

- Plastics

- Metal technology

- Plant engineering

- Production or manufacturing technology

- Automotive engineering

Why extraction

Protect employees and machines effectively from the risks of welding fumes and metal dusts. A clean working environment significantly increases the quality of your products and the service life of machines and tools.

Requirements for extraction systems:

- Extraction of dusts from the machines

- Extraction and filtration of fine dust

- Extraction of smoke during soldering and welding operations

- Removal of metal chips

- Extraction and filtration of oil mist and aerosols

The right extraction solution for your application

WET SEPARATOR

DEDUSTER

FUME FILTER

PRE-SEPARATOR

Your advantages

The flexible extraction solutions can be integrated into automated production processes or special requirements in mechanical engineering. We plan our extraction systems specifically for your process, including collection elements and pipe system.

LONG SERVICE LIFE

Clean air protects employees, protects machinery, tools, workpieces and increases the quality of your end product.

LOW FOLLOW-UP COSTS

Durable unit components and individually configured extraction systems keep operating and follow-up costs to a minimum.

ENERGY EFFICIENCY

Energetic components and the intelligent control system enable automatic power regulation and recirculated air or exhaust air operation. At the same time, heat recovery saves energy and heating costs.

WORLDWIDE 360° SERVICE

Via remote maintenance we support you worldwide, accompany you from consulting to installation and offer a comprehensive after-sales service.

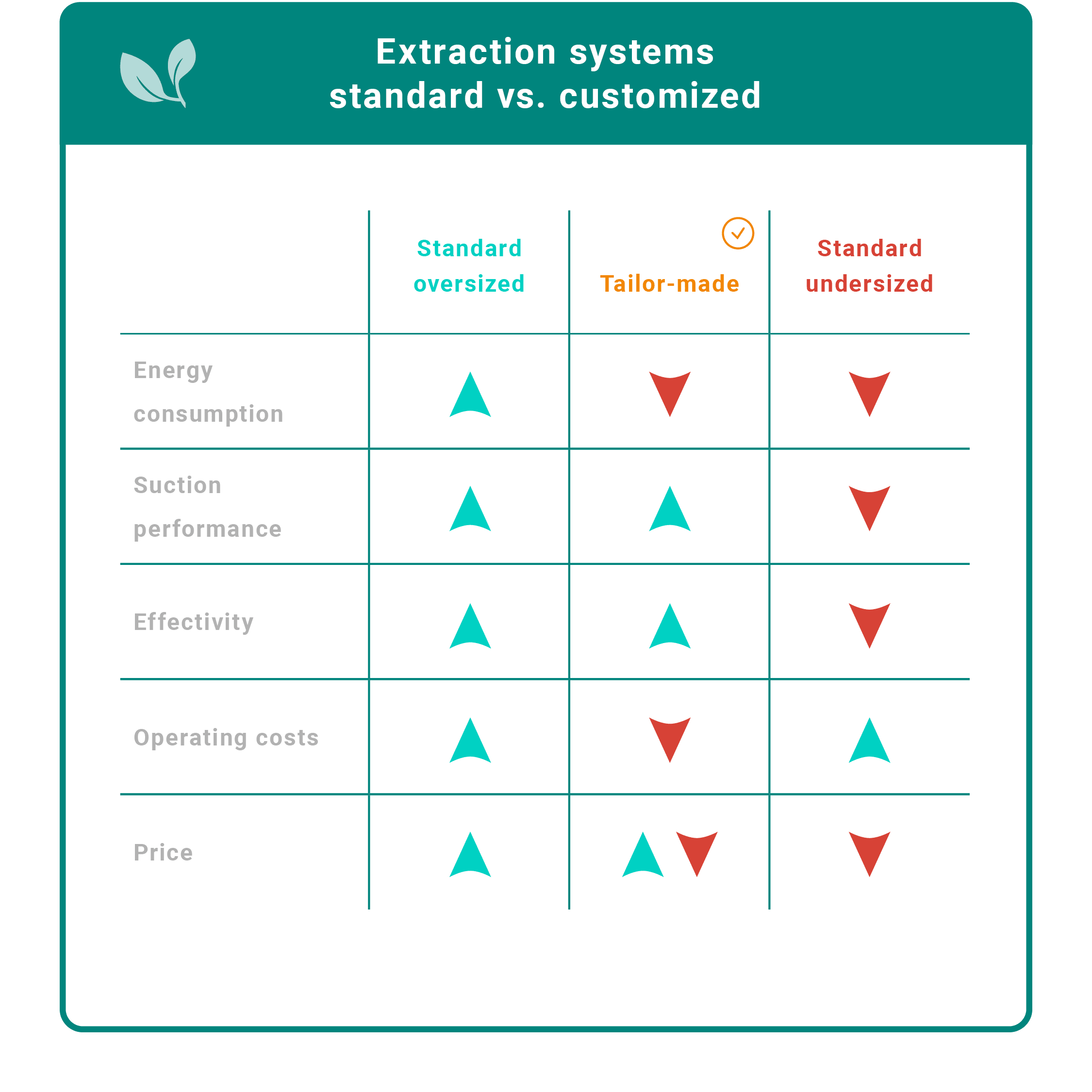

Customized extraction systems for mechanical engineering

We configure our systems optimally to the processes of our customers and can thus guarantee maximum extraction performance with minimum energy consumption. We comply with legal regulations and supply complete systems from a single source.

CAPTURES

- Extraction arms

- Extraction tables

- Extraction hoods

- Machine connection

- Individual capturing systems

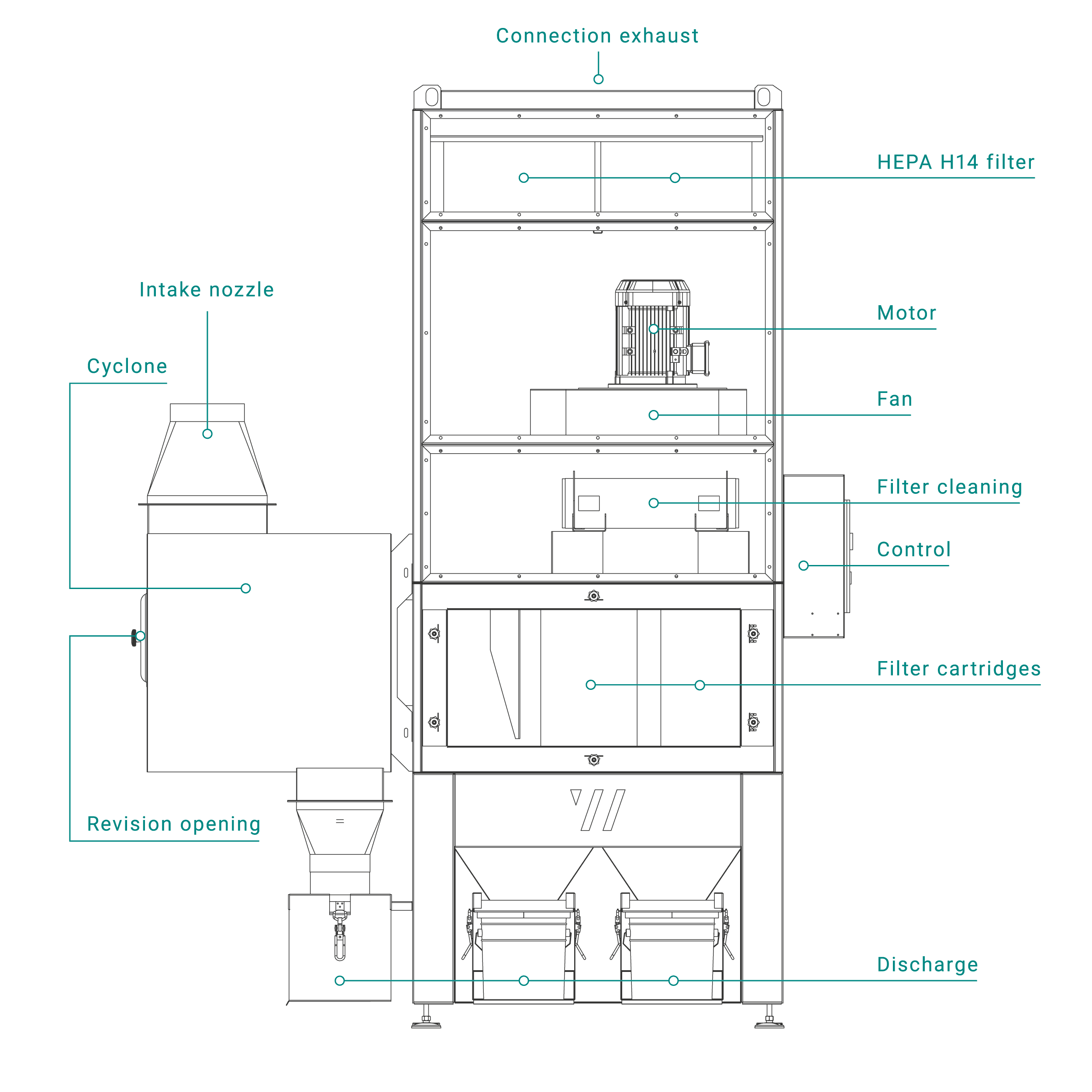

DISCHARGES

- Container (different sizes)

- Pinch valve

- Ball valve

- Sludge container (different sizes)

- Gate valve manual/el./pneumatic

- Continuous discharge systems

- Individual discharge systems

FILTER

- Robust, durable quality filters

- Separation efficiency 99.8%

- Cartridge/bag filter, stainless steel metal mesh

- Automatic cleaning

- HEPA 14 filter against carcinogenic stainless steel dusts

Units also available completely in stainless steel design

Fire and explosion protection at ABSAUGWERK

Flammable and explosive media such as gas, steam, mist or dust can cause serious fires and violent explosions. Our units are therefore equipped with special fire and explosion protection components.

- Flow-optimized design

- No deposits

- Automatic extinguishing system according to DIN/EN

- ATEX compliant design without zones

Pre-separators serve as spark traps and separate medium/coarse dust particles as well as glowing particles up to 99% in advance. This protects the main filters and ensures safe operation.

Customized piping systems for mechanical engineering

Pipe systems in extraction technology must be carefully planned and precisely designed to ensure optimum flow velocities and ideal pipe routing. Otherwise, serious fires, explosions or chronic respiratory diseases can be the result, as deposits can form in the pipe. Therefore, we take care of the entire planning and installation of the pipe systems ourselves, thus guaranteeing a coherent complete system.

World Wide WERK

Make your production ready for the future!

Via remote maintenance systems, our units are monitored in real time and, if necessary, an automatic alarm message is sent. In this way, malfunctions can be detected in good time and machine failures can be avoided.

• Diagnosis, configuration and programming via web

• Worldwide availability and fast support from experts

• Secure VPN encryption

Non-binding expert estimate

We offer comprehensive technical planning and consulting.

With our sales team, we will find the right solution for you and provide you with an individual offer.