WELDING

Welding + extraction = safe working

When welding metal parts in industry, harmful emissions such as smoke and fumes are released. To protect employees and to comply with applicable workplace limits (DGUV) and TRGS 528, these substances must be safely extracted and filtered. For effective extraction and economical investment, the technical design is crucial. Our flexible system components allow us to adapt our extraction systems specifically to your application, thus saving valuable energy and operating costs.

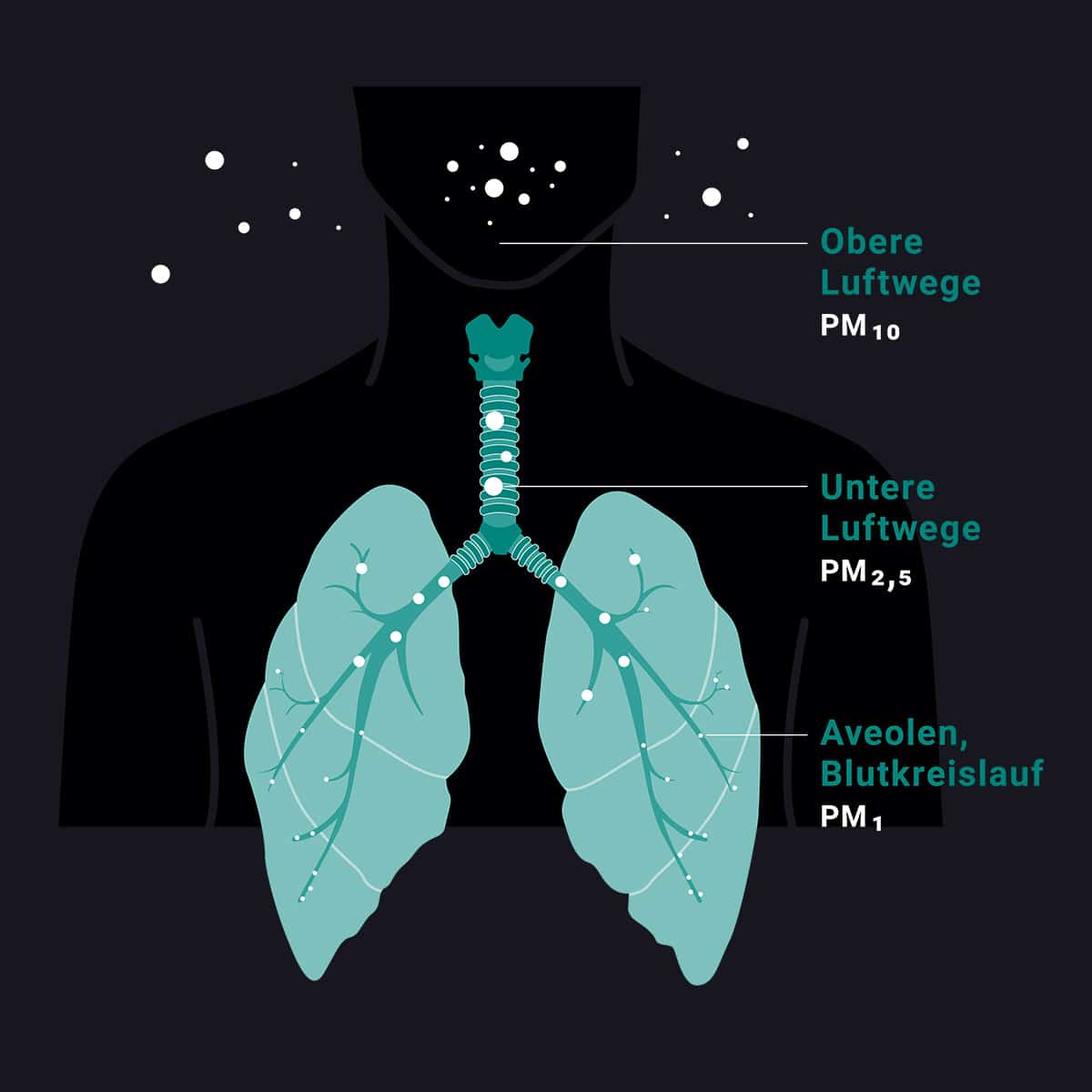

Cancer risk due to welding fumes

Due to their small size, perspiration smoke particles reach deep into the pulmonary alveoli (aveoli) when inhaled and settle there. Since 2018, welding fumes have been upgraded from possibly carcinogenic to to carcinogenic by the International Agency for Research on Cancer (IARC). This higher rating makes it imperative to minimize welding fume exposure. So-called »bystanders«, employees who weld only occasionally or work in the same room, are also at acute risk. In addition to arc welding, this also includes other processes such as gas welding (oxyacetylene process).

Extraction solutions for welding fumes

There are three technical approaches to the extraction of emissions during welding. In the case of several workplaces, large amounts of smoke and large workpieces, hall ventilation systems are usually more effective than spot extraction.

SINGLE PLACE EXTRACTION

Extraction of individual or several workplaces via an extraction system

FILTER TOWER

Filtering of the hall air via a stationary filter tower without a pipe system

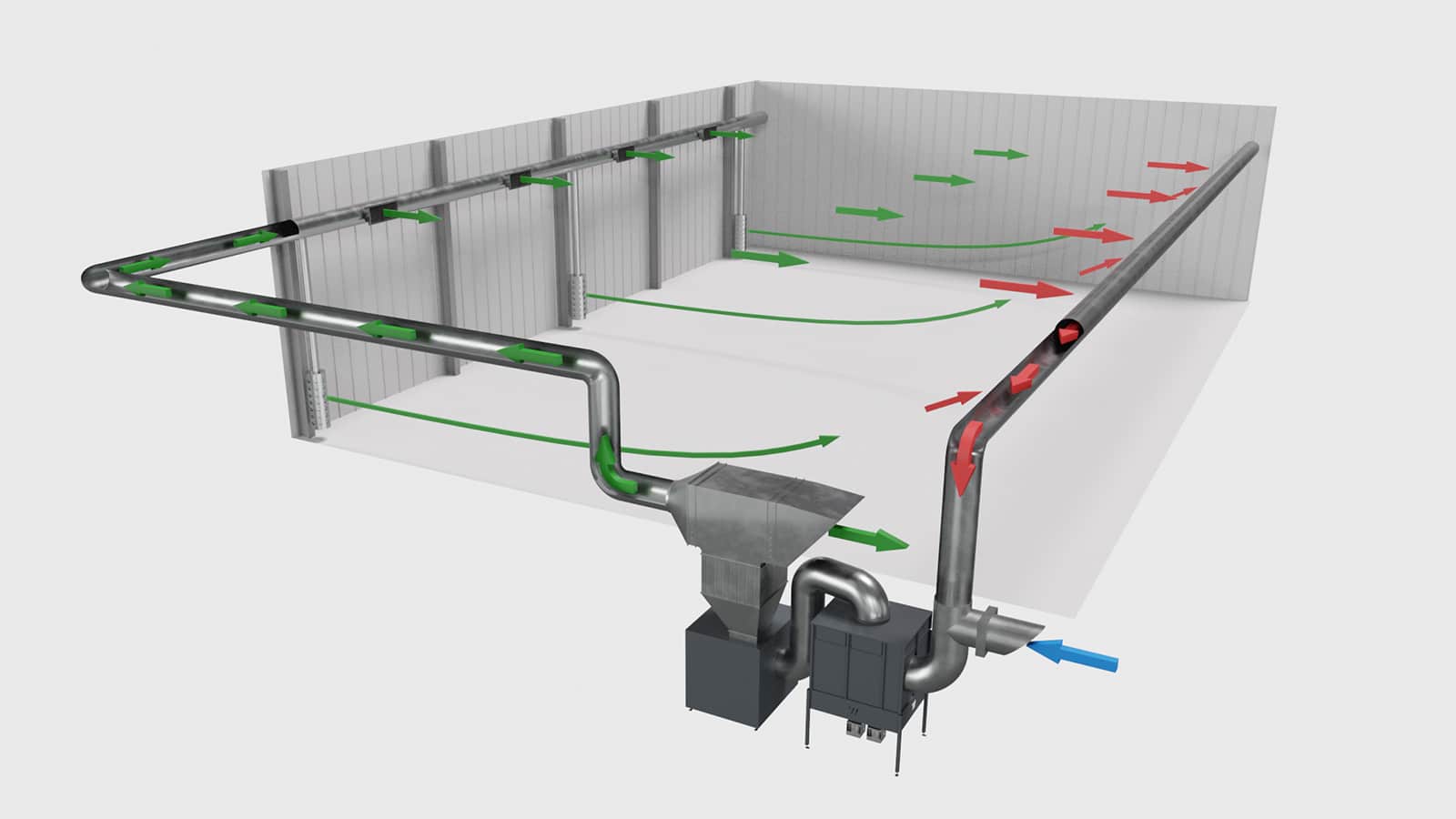

HALL EXTRACTION

Filtering of the hall air via a pipe system and stationary extraction unit

Welding fume filter from ABSAUGWERK

The fume filters of the R series were specially designed for the extraction of fine smoke and fume particles and can be optionally extended with a HEPA H14 filter for carcinogenic stainless steel dusts. In this process, the smoke is captured via an Extraction hood or Extraction arm and filtered in the extraction system via several filter stages. The cleaned air can then be fed back into the hall or outside.

Thanks to the numerous configuration options, we can offer an optimal and future-proof extraction solution for every application.

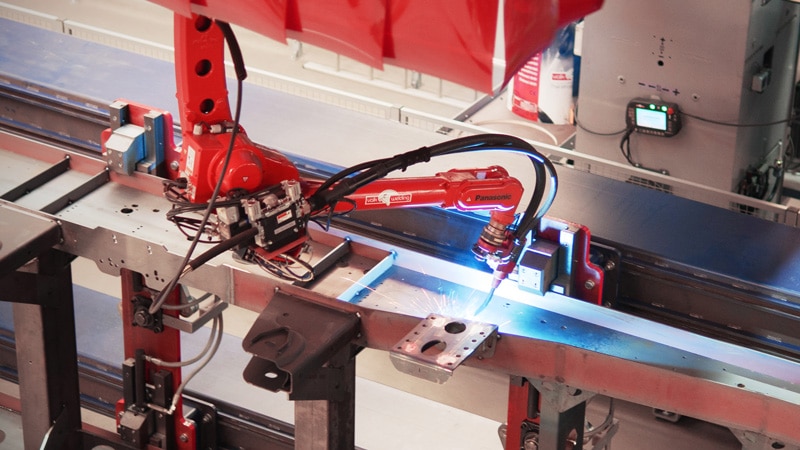

Extraction of welding robots

Welding robots are already a reality in numerous automated industrial processes. The factors of quality, speed and reach play a particularly important role here. They are used to support work that is difficult to perform using manual welding methods.

But here, too, fumes and gases are generated that are hazardous to health and must be extracted from the surrounding area, especially to protect employees. The extraction systems must also be capable of filtering large quantities of smoke and capturing them at the point of origin with sufficiently high extraction power.