Extraction aluminum dust

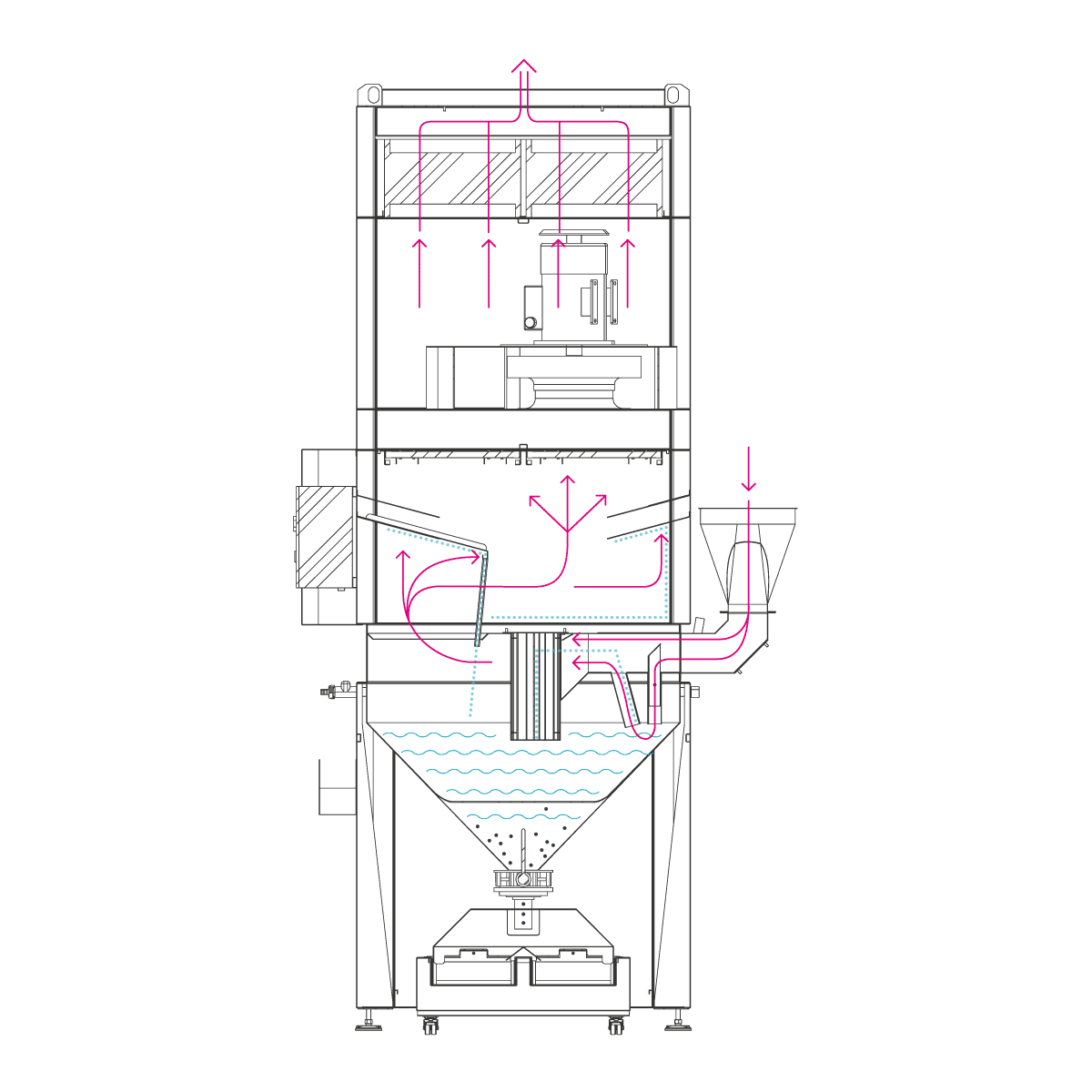

Wet separator for extraction of aluminum dust

Aluminum is one of the essential light metals in industry. When deburring, grinding, brushing or polishing aluminum, sparks are generated and an explosive dust-air mixture may result. Wet separators offer a safe and reliable extraction solution for aluminum, stainless steel and other metals through the technical use of water.

Patented wet separator technology

The revolutionary multi-chamber system separates sparks and dusts in the water, efficiently protecting against a fire or deflagration. High air velocities in the pipe system and the exhaust system itself, provide additional fire protection.

Wet separator for explosive aluminum dusts

Special ATEX directives apply to the extraction of combustible dusts in potentially explosive atmospheres, which must be observed in the technical design and construction of wet separators.

Explosion protection for wet separators

We develop our ATEX wet separators according to the primary explosion protection principle. This prevents explosive atmospheres from forming in the first place and is therefore one of the most economical and safest methods in explosion protection technology.

More about the primary explosion protection principle on Wiki Info.

ATEX components wet extraction

- Air speed in the pipe min. > > 20 m/s

- Automatic shutdown of the system

- Negative pressure and volume flow monitoring

- Motor according to ATEX

- Painted impellers

- Construction free of ignition sources and conductive

- No EX zones during operation

- All electrical components installed in conformity with ATEX

- Control cabinet outside the plant (no Ex-zone)