Deduster

P SERIES | S SERIESDeduster

P SERIES | S SERIESDedusters are extraction systems and are used both in industry and in the public sector to filter dust from the air we breathe. Processes such as grinding, deburring or cutting release dusts that must be extracted and filtered to protect the workforce. This means that occupational health and safety regulations and legal requirements can be complied with, and operators benefit from a clean hall and automatically extend the service life of their machinery.

Industrial deduster for dust, granules, fibers and chips

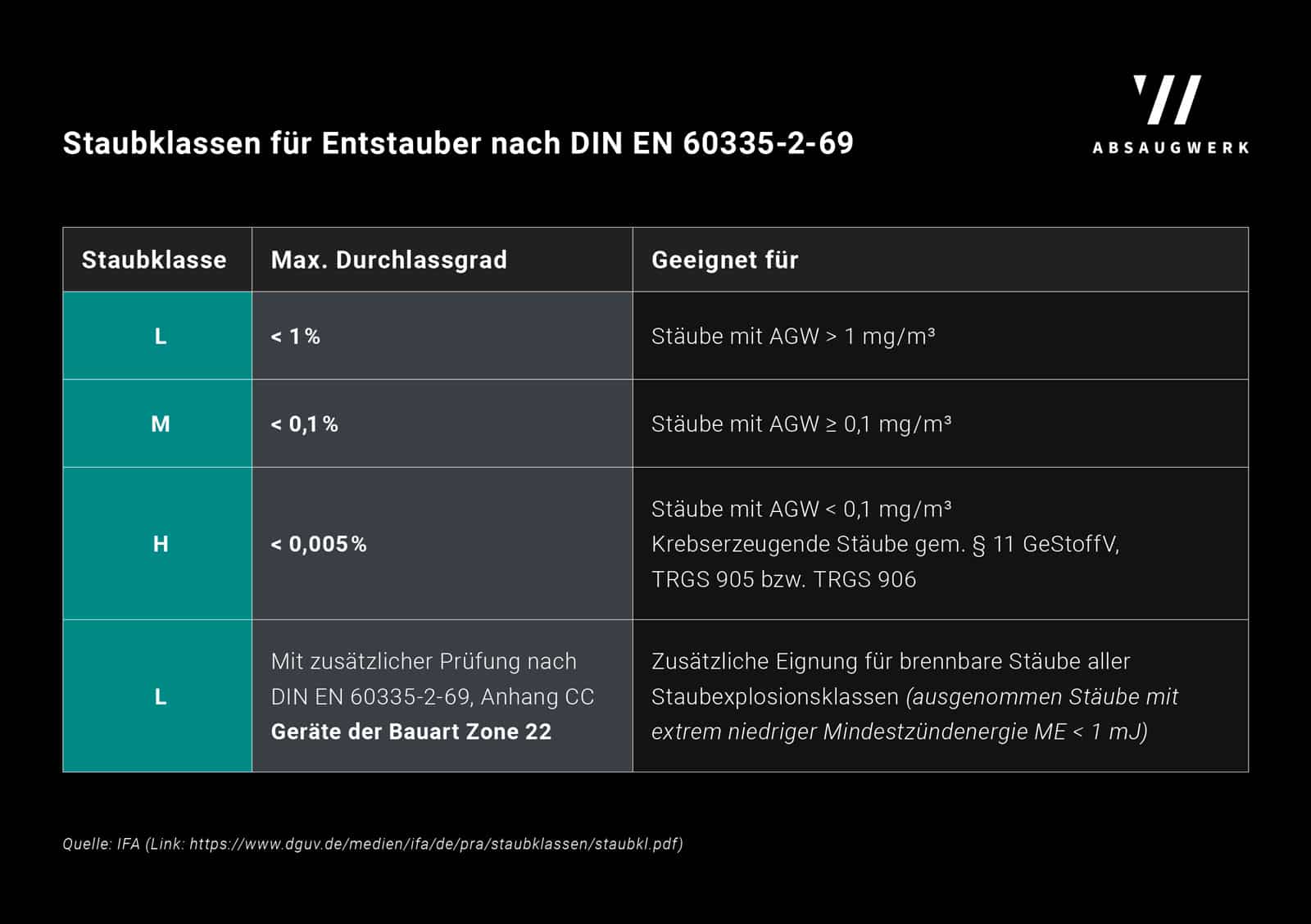

Numerous industrial processes generate dusts, chips, granules, fibers and flakes of different materials, particle sizes and chemical properties. Explosive and flammable media such as aluminium, copper or flour are particularly dangerous. The dedusters of the P (cartridge filter) and S (bag filter) series are available in various sizes and designs and can thus be individually configured. Due to the automatic Jet-Pulse filter cleaning, the dust cake is blown off the filters. This significantly increases the service life of the filters and minimizes operating costs. Against carcinogenic substances such as stainless steel or glass, an additional HEPA H14 filter is installed in the deduster. The cleaned air can then be fed back into the hall in recirculation mode or outside.

-

Individually configurable

-

High extraction power

-

Low energy consumption

-

Automatic filter cleaning

-

Flexible use for many industries

-

Energy-saving recirculation mode

INDIVIDUAL

COLORS

VARIOUS

FANS

DIFFERENT

FILTER VARIANTS

POSSIBLE

VERSIONS

Subscribe to our YouTube channel!

There we regularly publish new service and product videos on our dedusters and other extraction systems to make the use of our extraction systems even more customer-friendly.

Unit components deduster

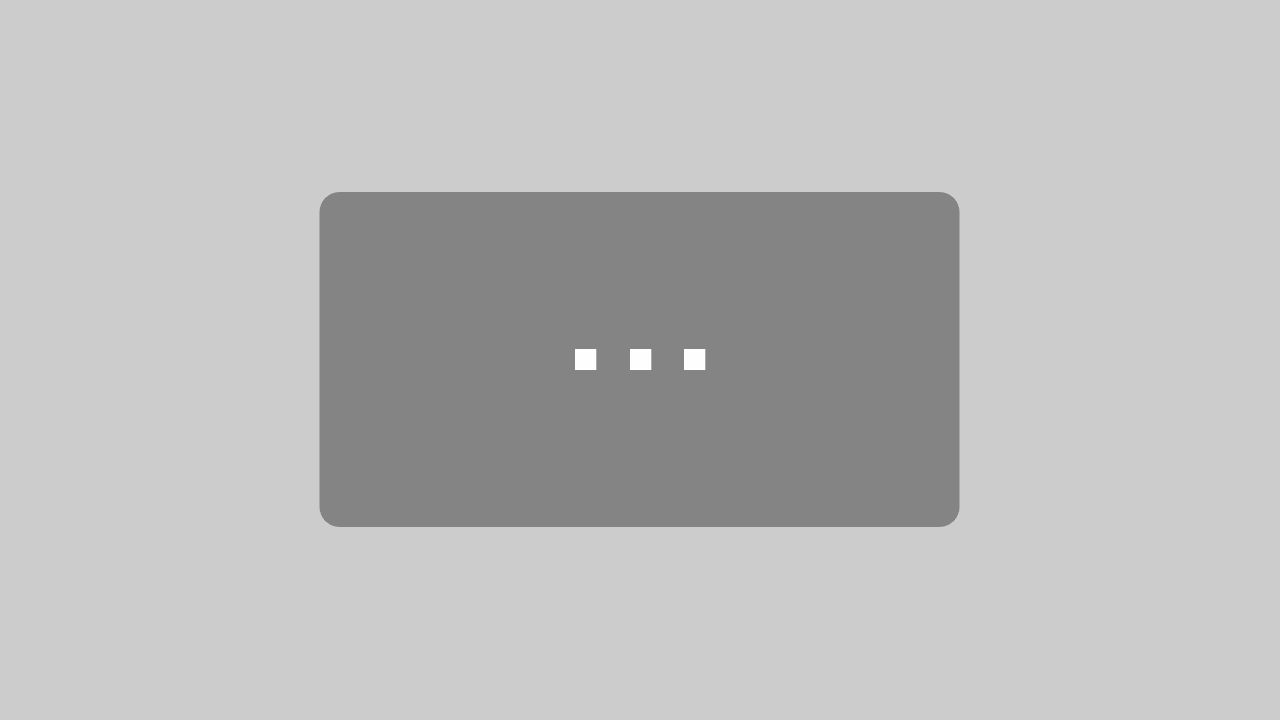

FILTER ELEMENTS

- Cartridge filter (diff. performances)

- Bag filter (diff. performances)

- Automatic Jet-Pulse cleaning

CAPTURE

- Extraction arm

- Extraction table

- Extraction hood

- Machine connection

- Individual capturing system

TECHNICAL DATA

- Motor power: 1.1–45 kW

- Extraction capacity: 2,400-40,000 m³/h

- Operating time: 24 h / 7 days

DISCHARGE

- Drawer

- Container

- Bucket

- Container

- Automatic discharge (e.g. cellular wheel sluice)

- Individual discharge system

Options & variations

HEPA H14 FILTER

Against carcinogenic substances

ACTIVATED CARBON FILTER

Against gases and odors

EXPLOSION PROTECTION

ATEX execution

Fire protection

Automatic extinguishing system

noise protection

Effective and safe

PRE-SEPARATOR

For large amounts of material

PRECOAT-UNIT

Premium filter protection

CROSS HEAT EXCHANGER

Effective heat recovery

DIFFERENT FANS

Medium/high pressure, high vacuum

INTELLIGENT CONTROL

Versatile operating options

unit color & branding

Individual as desired

Explosion protection at

ABSAUGWERK

In the right mixing ratio with oxygen and an effective ignition source, flammable and explosive media in the form of gas, vapor, mist or dust can cause serious fires and violent explosions. This can injure people, destroy buildings and plant components, and ignite other flammable substances.

So-called ATEX directives (ATmosphères EXplosibles) therefore apply to industrial extraction systems such as dedusters.

ATEX COMPONENTS Deduster

- Air speed in the pipe min. > > 20 m/s

- Negative pressure and volume flow monitoring

- Motor according to ATEX Zone 2

- Construction free of ignition sources and conductive

- No ex-zones during operation

- All electrical components installed ATEX-compliant

- Electrical cabinet outside the system

Environmental protection & sustainability

We develop economical and energy-saving deduster and extraction systems using state-of-the-art technology. For a climate-friendly industry of today and tomorrow.

High-quality workmanship

for a long service life

Lower energy costs

per year

Certified

HEPA H14 filter

Summer/winter changeover

through intelligent control

Reduced heating costs

due to cross heat exchanger

Minimized

pollution

No expensive

EX protection components

Automatic regulation

of the air flow rate

References deduster

Our deduster series is individually configurable and can thus be optimally adapted to the various processes in a wide range of industries. For our customer Grammer from the automotive industry, we have developed and installed two work cabins with a deduster including fire protection and ATEX concept for carcinogenic glass dusts.

Grammer

We provided the world’s leading supplier of seating solutions for commercial vehicles and interior solutions for the automotive industry with two work cabs. equipped, in which grinding and polishing work is carried out in 3-shift operation. The harmful dust mixture released during polishing is extracted with the help of our deduster and effectively filtered out of the booth air.

FAQs

We are happy to help!

We provide you with comprehensive technical expertise for the planning and consultation of your deduster. We work together to develop customized solutions and will be happy to provide you with an individual offer.