Extraction cabins

Extraction cabins against welding fumes and dust

Which extraction system and which cabin design is optimal for your application depends on numerous factors that we take into account during planning. Only in this way can we offer you a future-proof complete system that is sustainable and economical in operation. Thanks to our know-how, we also modernize existing extraction cabins or overhaul already integrated extraction systems.

Advantages

- Individually configurable extraction cabins

- Can be combined with all extraction systems

- Optimal dust and welding fume extraction

- Targeted and energy-saving extraction

- Effective sound insulation

- Targeted temperature control

- High-quality extraction systems »Made in Germany«

- 360° service: consulting, installation, pipe planning, after-sales

Added value

- Heating cost savings through heat recovery

- Effective health protection

- Constant compliance with workplace limits

- No pollution of the environment

- Better working climate

- Flexibility for future hall use

- Increased productivity, health and employee satisfaction

Get individual advice now

We offer you a free and non-binding expert estimate!

Ventilation techniques for extraction cabins

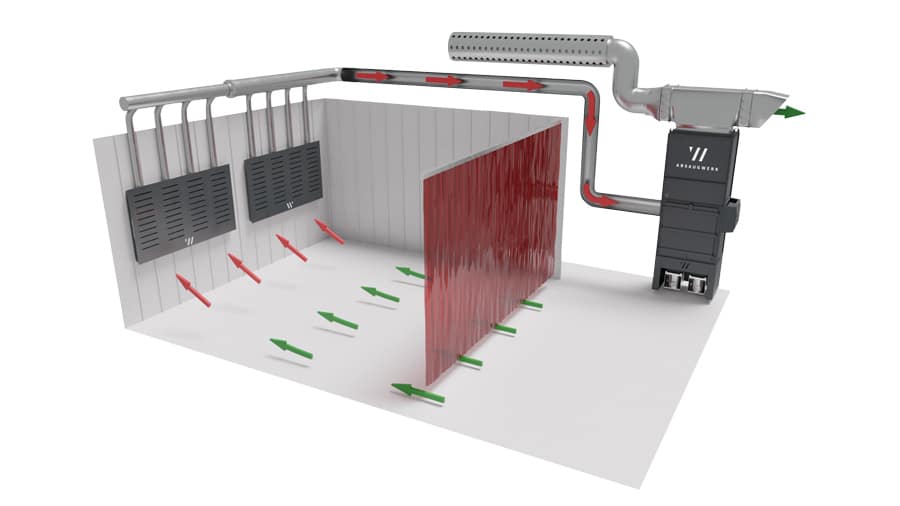

Post flow open:

- One-sided detection

- Supply air through separating curtain

- No air recirculation

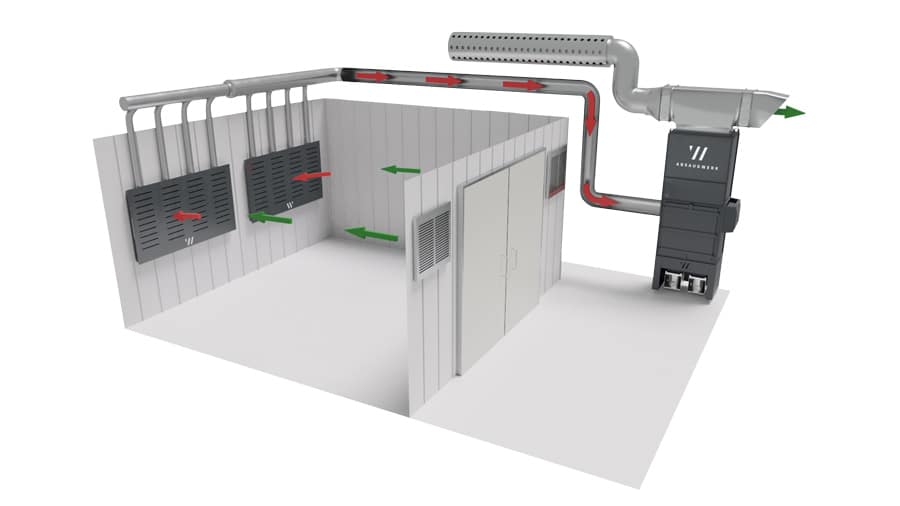

Post flow targeted:

- One-sided detection

- Supply air through air inlets

- No air recirculation

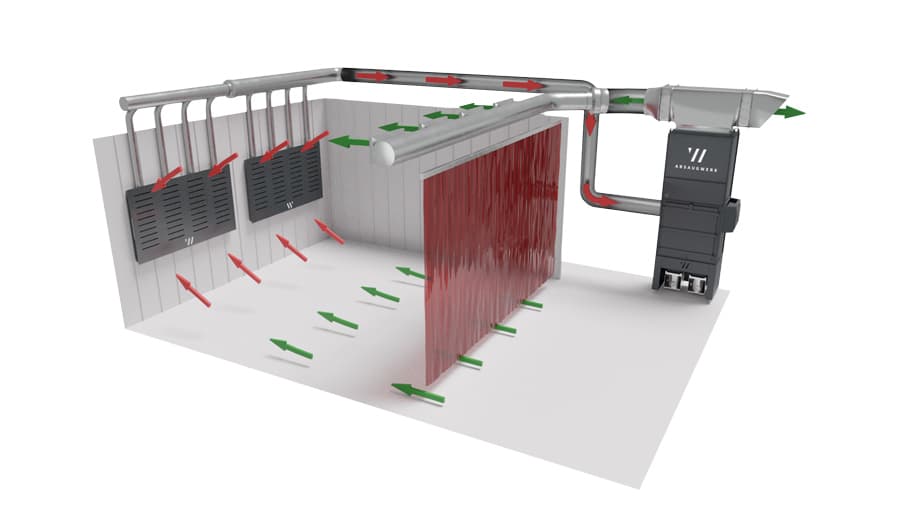

Post flow mixed:

- One-sided detection

- Supply air through separating curtain and displacement outlets or jet nozzles

- Air recirculation into the cabin

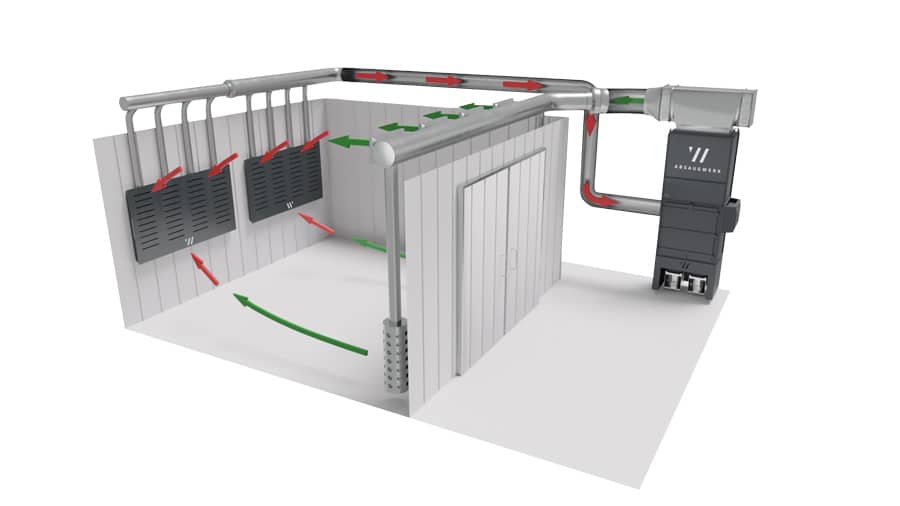

Post flow closed:

- One-sided detection

- Supply air through displacement outlets or jet nozzles

- Air recirculation into the cabin

PROCESSES

Welding, grinding, deburring, milling, flexing, lasering

CAPTURES

Extraction table, extraction arm, extraction hood, extraction column, individual extraction systems

APPLICATION

Work booth

Soundproof booth

Machine enclosure

Options for extraction cabins

HEPA H14 FILTER

Against carcinogenic substances

ACTIVATED CARBON FILTER

Against gases and odors

EXPLOSION PROTECTION

ATEX execution

Fire protection

Automatic extinguishing system

CAPTURES

Numerous systems

HEPA H14 FILTER

Against carcinogenic substances

ACTIVATED CARBON FILTER

Against gases and odors

EXPLOSION PROTECTION

ATEX execution

Fire protection

Automatic extinguishing system

CAPTURES

Numerous systems

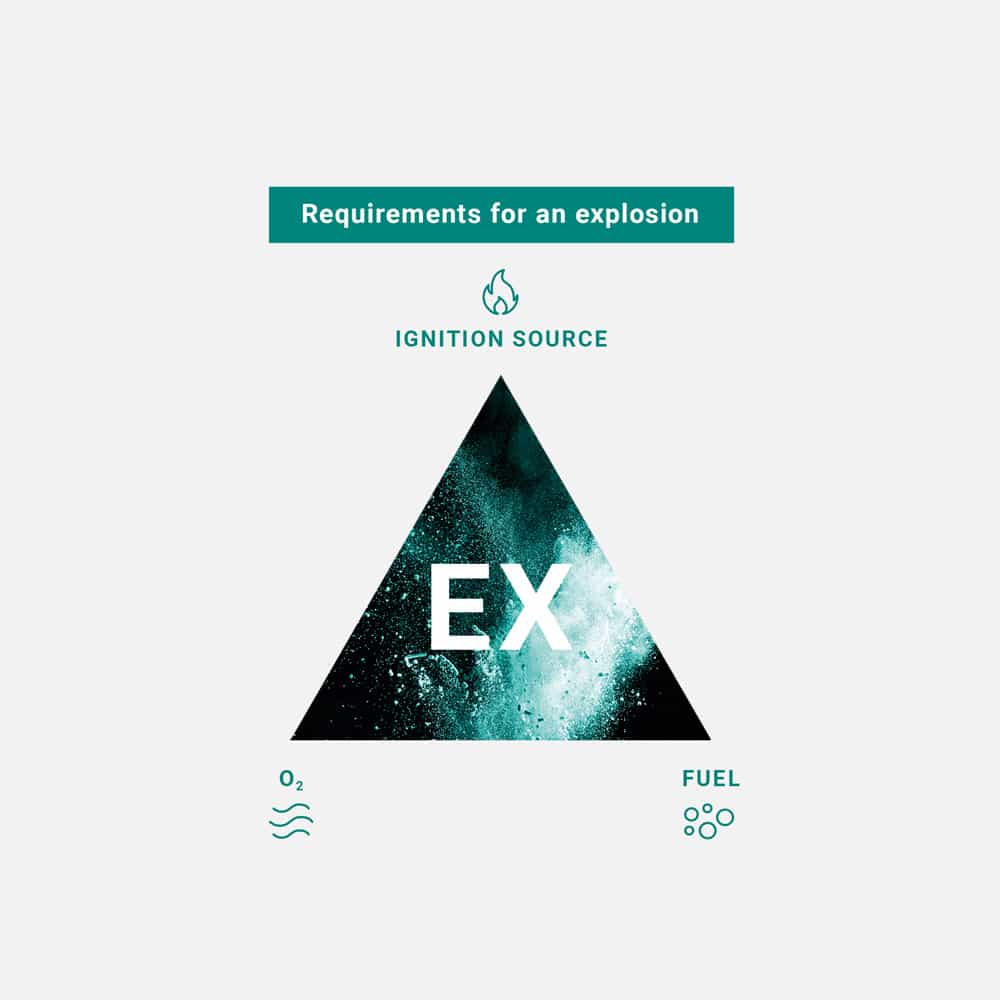

Explosion protection for extraction cabins

Explosion protection for extraction cabins Industrial processes such as grinding or deburring release not only visible but also invisible fine dusts that can trigger dangerous fires and explosions. Explosive dusts include organic substances such as flour, coffee or cellulose, as well as aluminum or magnesium. In order to prevent an explosion, electrical components and other parts must be installed in the work cabin in compliance with ATEX.

Customized extraction systems by ABSAUGWERK

FILTER TOWER

FUME FILTER

DEDUSTER

FILTER UNITS

Assembly and installation

of your extraction booth

We accompany you personally in every phase of the completion of your extraction booth, including piping and extraction system. From the first consultation to planning, installation, commissioning and after-sales service!

Environmental protection & sustainability

We develop economical and energy-saving extraction systems and state-of-the-art extraction booths. For a climate-friendly industry of today and tomorrow.

Heating cost savings

up to 70 %

Lower energy costs

per year

Low

maintenance costs

Low cleaning costs

for tools, machines and hall

Minimized

pollution

Sustainable and

innovative technology

Flexible use & redesign

of production

Constant

temperature level

References extraction cabins

Every application is unique. Therefore, we pay attention to numerous parameters during the technical design in order to guarantee you the most economical solution.

Request for quotation extraction cabin

We offer comprehensive technical planning and consulting for your work or extraction cabin. As a manufacturer, we also find special solutions and provide you with an individual offer. Request now without obligation!