FILTER UNITS

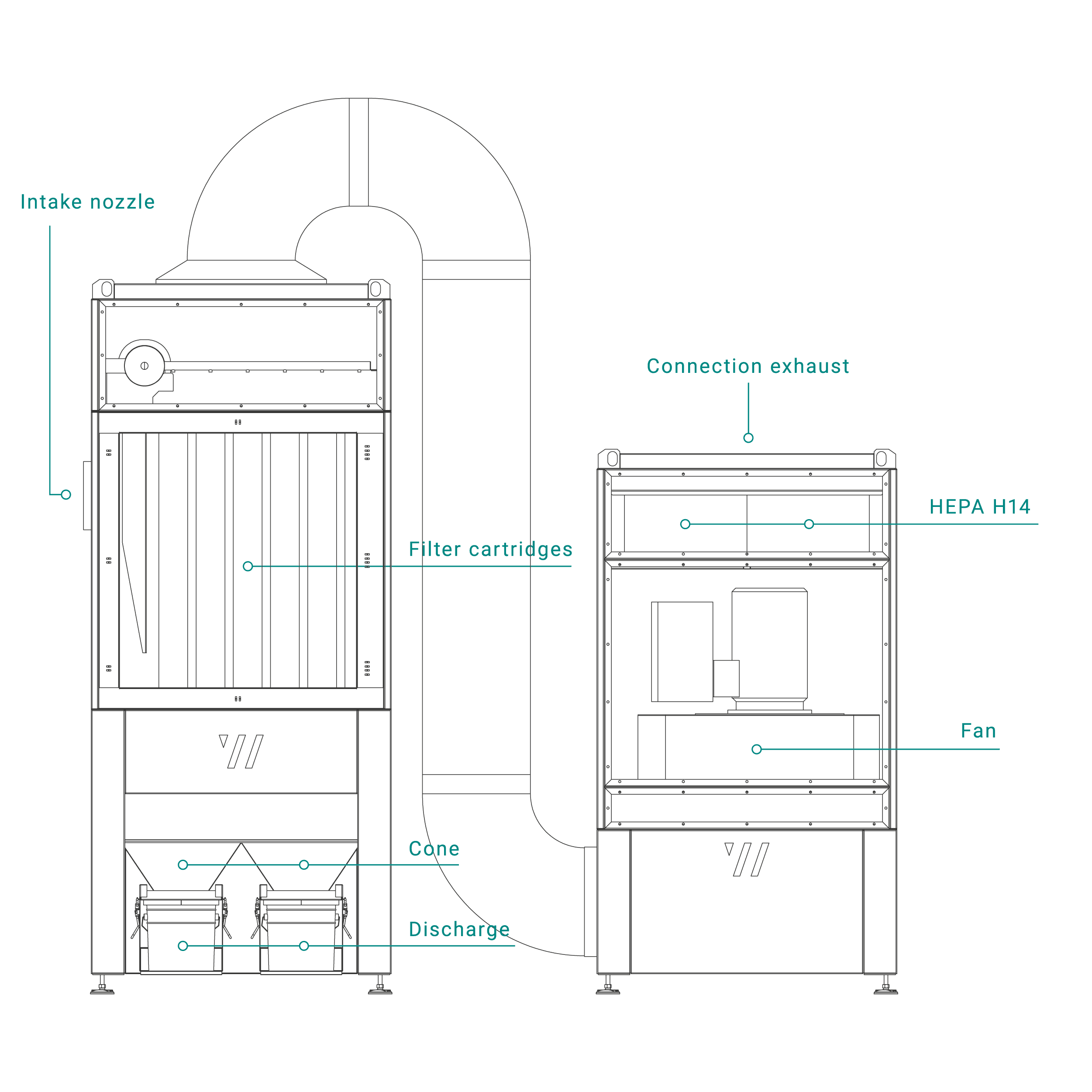

S SERIESFilter units can be set up individually or combined and extract several workplaces at once. The extraction elements with separate fan are used especially for large quantities of air and material.

Powerful & space saving

The S series filter units are available in various sizes and executions and filter captured dust and chips using high-quality bag filters. The cleaned air can then be fed back into the hall or outside. For carcinogenic substances such as stainless-steel, a HEPA H14 filter is used.

-

For large amounts of air and media

-

Extraction of several individual workplaces

-

Powerful fans

-

Extensive pipe systems

-

Low height and footprint

-

Robust and weather resistant

-

Recirculating air or exhaust air operation possible

MEDIA

Dust

Chips

Granules

Fibers

Flakes

Lints

PROCESSES

Sawing, Separating, Grinding, Cutting, Polishing, Deburring etc.

PERFORMANCE

max. 40,000 m³/h

per filter unit

Unit components

FILTER

- Bag filter (diff. performances)

- Automatic Jet-Pulse cleaning

CAPTURE

- Extraction arm

- Extraction table

- Extraction hood

- Machine connection

- Individual capturing system

TECHNICAL DATA

- Motor power: 1.1–45 kW

- Fan capacity: 2,400–40,000 m³/h

- Operating time: 24 hours per day

DISCHARGE

- Drawer

- Container

- Bucket

- Container

- Automatic discharge (e.g. cellular wheel sluice)

- Individual discharge system

Options & variations

HEPA H14 FILTER

Against carcinogenic substances

ACTIVATED CARBON FILTER

Against gases and odors

V2A-EXECUTION

Hygienic & stainless

EXPLOSION PROTECTION

ATEX execution

Fire protection

Automatic extinguishing system

noise protection

Effective and safe

PRE-SEPARATOR

For large amounts of material