FUME FILTER

R SERIESFUME FILTER

R SERIESFume filters bind harmful smoke in high-quality cartridge filters and ensure a healthy working environment. In this way, applicable occupational exposure limits can be permanently complied with. For optimal welding fume extraction, we offer various capture elements such as extraction hoods, extraction arms or complete extraction cabins.

Contact us for a non-binding consultation on your application!

Fume filter and welding fume filter for fume and dust

During welding, robotic welding, laser cutting, cutting, soldering and other metalworking processes, smoke and smoulder are released that must be reliably extracted to protect people and machines. When welding stainless steel, the chromium and nickel content produces carcinogenic emissions, which are bound via the additional W3 design or the certified HEPA H14 filter. The cleaned air can then be fed back into the hall (recirculation mode) or outdoors.

As a manufacturer of fume filters, we develop our extraction systems ourselves and can therefore also economically produce special extraction solutions for special applications. The flexible components allow us to supply customized extraction systems for almost any process that are energy-saving and cost-effective to operate.

-

High extraction power with low energy consumption

-

Cleanable durable filter components

-

Flexible use due to numerous options

-

Recirculation and exhaust air mode

INDIVIDUAL

COLORS

VARIOUS

FANS

DIFFERENT

FILTER VARIANTS

POSSIBLE

VERSIONS

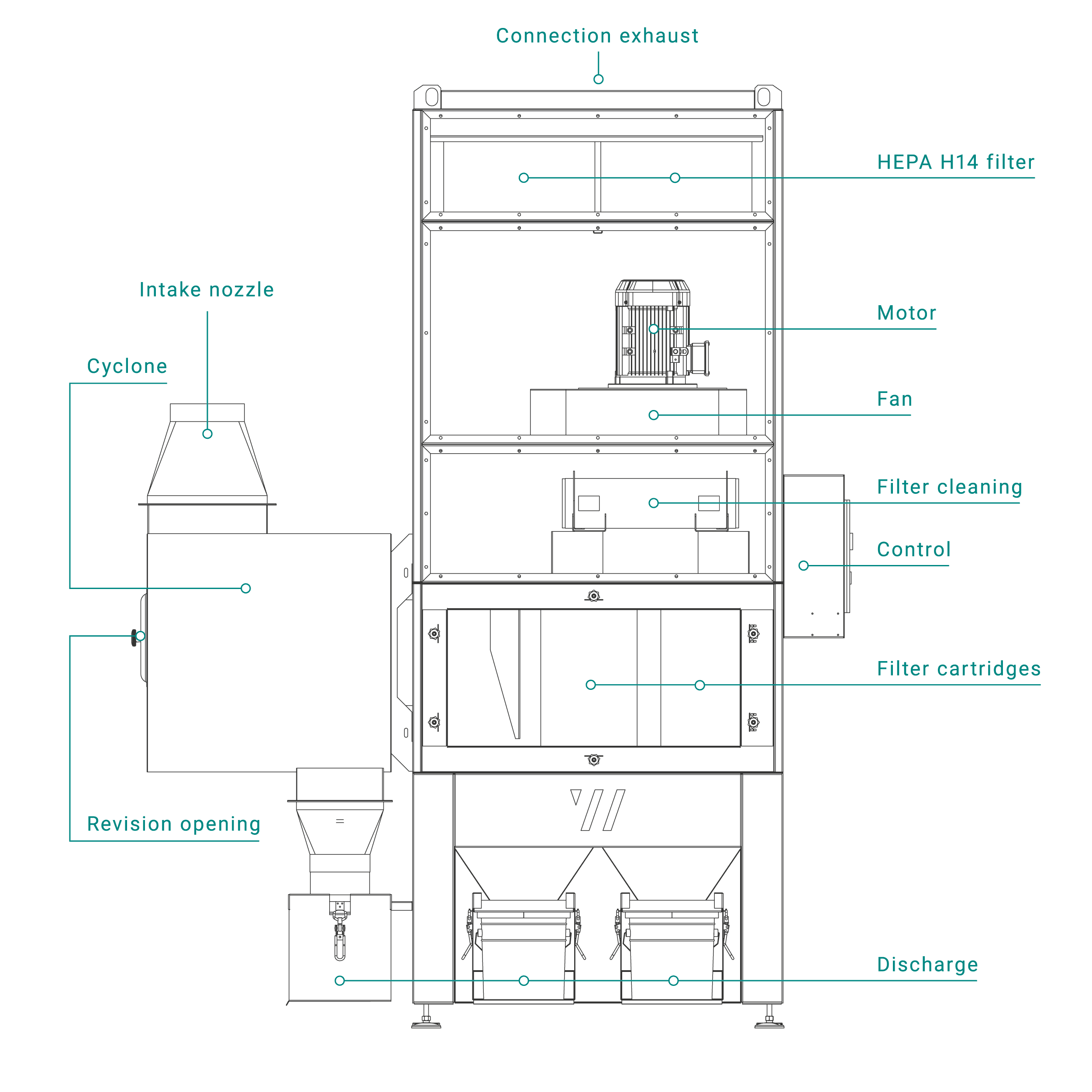

Fume filter function

Fume filters of the R series are individually configurable with their different sizes and various designs and can thus be precisely tailored to the respective process. In the design of the extraction systems, emphasis is placed on high-quality components and optimum performance in order to keep energy and operating costs to a minimum and to protect the environment.

Fig. : Fume filter with various options and precoat unit

Unit components fume filter

FILTER

- Cartridge filter (diff. performances)

- Automatic Jet-Pulse cleaning

CAPTURE

- Extraction arm

- Extraction table

- Extraction hood

- Machine connection

- Pipe system

- Individual capturing system

TECHNICAL DATA

- Motor power: 1.1–45 kW

- Fan capacity: 2,400–40,000 m³/h

- Operating time: 24 hours per day

DISCHARGE

- Drawer

- Container

- Bucket

- Container

- Automatic discharge (e.g. cellular wheel sluice)

- Individual discharge system

Options & variations

HEPA H14 FILTER

Against carcinogenic substances

ACTIVATED CARBON FILTER

Against gases and odors

EXPLOSION PROTECTION

ATEX execution

Fire protection

Automatic extinguishing system

noise protection

Effective and safe

W3-EXECUTION

Welding fume class for high-alloy steels

PRE-SEPARATOR

For large amounts of material

PRECOAT-UNIT

Premium filter protection

CROSS HEAT EXCHANGER

Effective heat recovery

DIFFERENT FANS

Medium/high pressure, high vacuum

INTELLIGENT CONTROL

Versatile operating options

unit color & branding

Individual as desired

Explosion protection at

ABSAUGWERK

In the right mixing ratio with oxygen and an effective ignition source, flammable and explosive media in the form of gas, vapor, mist or dust can cause serious fires and violent explosions. This can injure people, destroy buildings and plant components, and ignite other flammable substances.

For this reason, so-called ATEX directives (ATmosphères EXplosibles) apply to industrial extraction systems.

ATEX-COMPONENTS

- Air speed in the pipe min. > > 20 m/s

- Negative pressure and volume flow monitoring

- Motor according to ATEX Zone 2

- Construction free of ignition sources and conductive

- No ex-zones during operation

- All electrical components installed ATEX-compliant

- Electrical cabinet outside the system

Environmental protection & sustainability

We develop economical and energy-saving extraction systems using state-of-the-art technology. for a green industry of today and tomorrow.

High-quality workmanship

for a long service life

Lower energy costs

per year

Certified

HEPA H14 filter

Summer/winter changeover

through intelligent control

Reduced heating costs

due to cross heat exchanger

Minimized

pollution

No expensive

EX protection components

Automatic regulation

of the air flow rate

We are happy to help!

We provide you with comprehensive technical expertise for the planning and consultation of your fume filter. We work together to develop customized solutions and will be happy to provide you with an individual offer.