OIL MIST SEPARATOR

for emulsions & aerosolsOIL MIST SEPARATOR

for emulsions & aerosolsOil mist separator for industry

Oil mist separators are used in industry for extracting fine emulsion mist that is produced by the use of cooling lubricants in machine tools and machining centers. In order to comply with statutory occupational health and safety regulations, the oil-containing pollutants in the air must be effectively separated. The emulsion mist separators bind mist, vapors, aerosols or fume via several filter stages and neutralize unpleasant odors from the hall air. This protects employees, machinery and the purity of your end product.

The separated cooling lubricants collect in a container and can be fed back into the machine tool. As a manufacturer of oil mist separators, we are constantly developing our extraction systems and also manufacture individual extraction solutions for special processes.

Contact us for a non-binding consultation on your application!

Oil mist separator for aerosols, emulsions and vapors

The use of coolants / lubricants in production processes such as milling, grinding or machining, releases fine oil mists, emulsion mists, aerosols and fumes. These are deposited on machinery, floors or walls. The respirable pollutants endanger employees, contaminate production and increase the risk of fire and accidents.

Extraction solutions from ABSAUGWERK are configured and manufactured specifically for the respective process and the requirements of our customers. Depending on the nature of the extracted oil mists, several filter stages made of stainless steel mesh and additional HEPA H14 afterfilters are used for fine and carcinogenic particles. The stainless steel knitted filters can be easily and inexpensively washed out with a conventional high-pressure cleaner.

The cooling lubricants are collected in a container and can be fed back into the machining center. Due to the high filtration efficiency of the filters, the units are particularly low-maintenance and have a uniquely long filter service life. The cleaned air can then be returned to the production hall in recirculation mode or discharged outside as exhaust air.

-

High extraction performance with low energy consumption

-

Washable stainless steel mesh filters

-

The longest filter life in the industry

-

Reuse of the cooling lubricants

-

Quality directly from the manufacturer

Application areas

Metalworking

Plastics industry

Extrusion

Cable manufacturing

Automotive industry

Pharmaceutical industry

Chemical industry

Food industry

Toolmaking

Roller production

PROCESSES

Turning, grinding, milling, drilling, sawing etc.

MACHINES

Milling machines

Machine tools

Lathes

CNC machines

MEDIA

Oil and emulsions

Vapors

Aerosols

Spray mist

Moist particles

Configurable oil mist separators – specifically for your process

Every application is unique, which is why we offer tailor-made oil mist filters specifically for your requirements, also with a separate fan for particularly high engine outputs on request. As a manufacturer of industrial extraction systems, we ensure the quality of our extraction systems by operating the entire service chain ourselves and offering integrated extraction solutions: Pipe system, sound insulation, fire protection, explosion protection as well as individual captures or discharge systems.

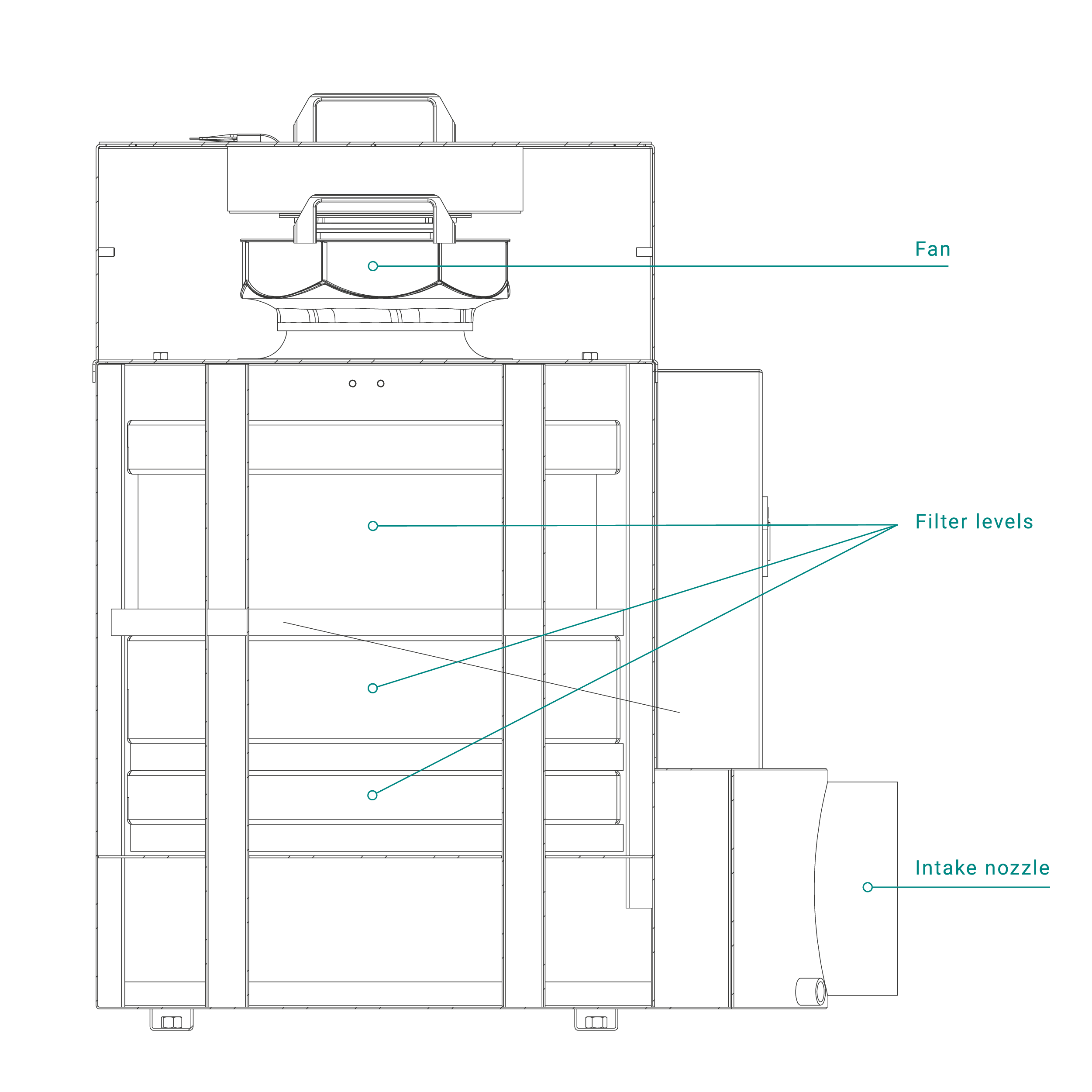

Oil mist separator function

The filter systems are usually connected directly to the respective machine, aspirate the media and filter them through several filter stages. The cleaned air can then be fed back into the room in recirculation mode or outdoors as exhaust air. The filtered emulsion drips off the stainless steel mesh filters and is fed back into the processing center via a siphon hose. This saves material and costs.

Thanks to the adjustable air output and the integrated energy-saving motor, operating costs remain low. The extraction power can be individually adjusted to the respective process. The stainless steel mesh filters used can be conveniently cleaned in the cleaning station. Cleanbox cleaning station and cleaned with a conventional high-pressure cleaner. The polluted water collects in a tub and is drained off via a drainage nozzle.

System components oil mist extraction

FILTER MEDIA

- Washable stainless steel mesh filters

- Cassette filter

CAPTURE

- Extraction arm

- Extraction table

- Extraction hood

- Pipe system

- Machine connection

- Room detection

- Individual capturing system

TECHNICAL DATA

- Motor power: 1.1–15 kW

- Fan capacity: 2,400-17,900 m³/h

- Operating time: 24 hours per day

DISCHARGE

- Siphon connection

- Individual discharge system

Options & variations

HEPA H14 FILTER

Against carcinogenic substances

ACTIVATED CARBON FILTER

Against gases and odors

V2A-EXECUTION

Hygienic & stainless

HEPA H14 FILTER

Against carcinogenic substances

ACTIVATED CARBON FILTER

Against gases and odors

V2A-EXECUTION

Hygienic & stainless

Energy saving with ABSAUGWERK

Thanks to the high separation efficiency of our extraction systems, the filter systems are also suitable for recirculating air operation. A frequency converter automatically adjusts the suction power to your production conditions and saves valuable energy. Already during the development of our extraction systems we pay attention to minimum resistances in the pipe system and the system as well as an optimal air flow. Thus, we produce high-performance extraction systems with very low energy consumption compared to standard systems.

Energy-saving

Recirculation mode

Low

resistances

Highly efficient

IE5 fans

Heating cost savings

through heat exchangers

Recirculation of the

cooling lubricant

Minimized

pollution

Low

maintenance costs

Automatic regulation

of the air flow rate

Low-maintenance oil mist extraction and long filter service life

As a manufacturer of extraction systems and oil mist separators, the quality of our systems has the highest priority. To ensure a long service life for our extraction systems, we install high-quality components and handle the entire service chain ourselves, from consulting to after-sales service. The installed metal mesh filters made of stainless steel can be washed out with a conventional high-pressure cleaner and separate oil mist so efficiently that the second and third filter stages are hardly affected. This significantly increases the service life of all installed filters and saves costs in operation and service. Each of our extraction units is individually tested and only leaves the WERK fully functional.

References

Every application is unique. When technically designing an oil mist extraction system, we therefore pay attention to numerous parameters in order to guarantee you the most economical solution.

D. La Porte Söhne

»There is a world of difference between the air quality before and after installation of the oil mist separator. The Employer’s Liability Insurance Association was also enthusiastic about the effectiveness of the extraction system. The air quality and temperature in the hall have improved tremendously. This was particularly important to us because our employees are our most important asset.«

Joachim Pirdzuns, Plant Manager D. La Porte Söhne GmbH

FAQs

We are happy to help!

We provide you with comprehensive technical expertise for the planning and consultation of your oil mist separator. We work together to develop customized solutions and will be happy to provide you with an individual offer.