OHM & HÄNER metal works

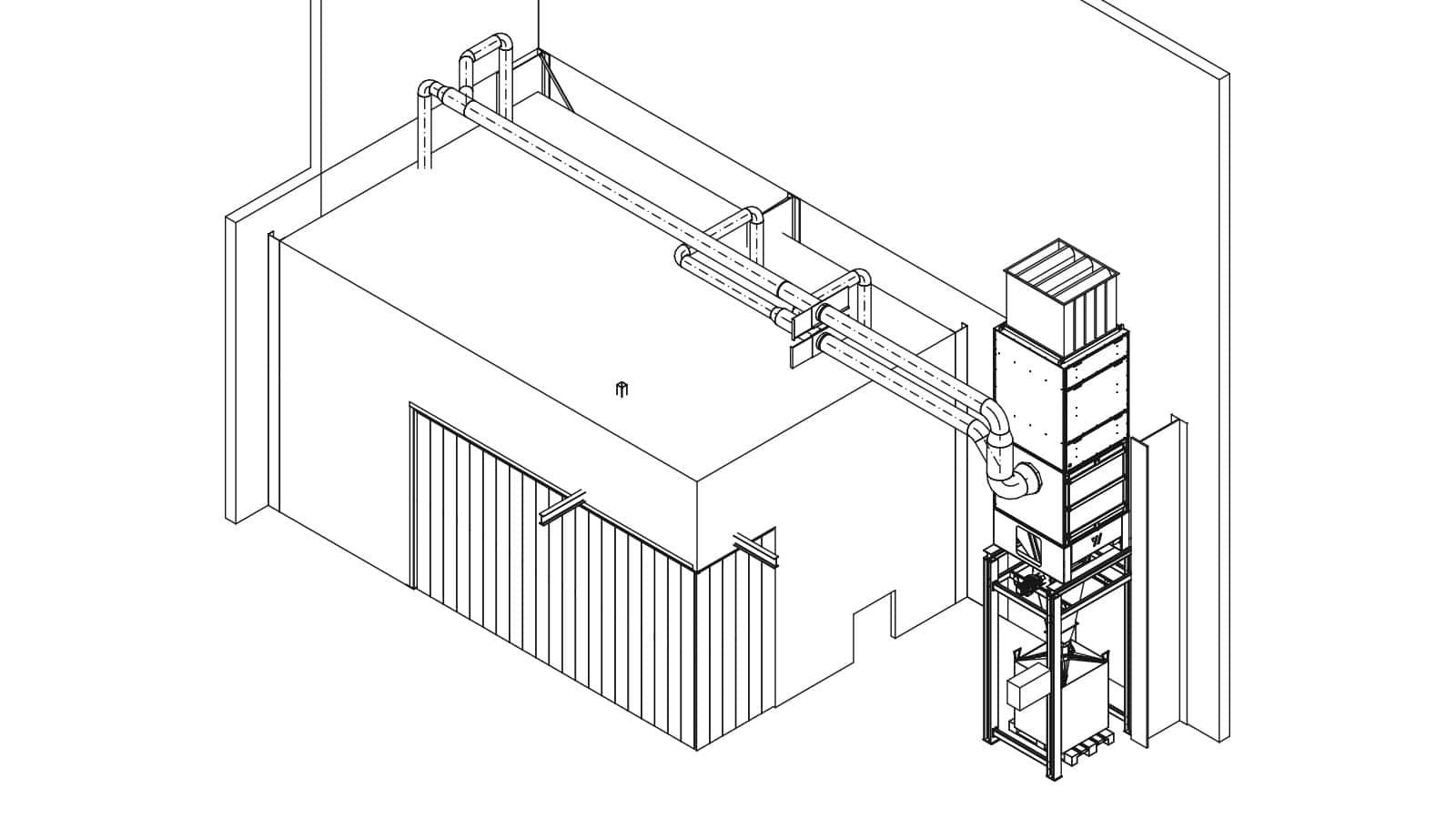

ATEX deduster for indoor use

Ohm & Häner Metallwerk GmbH & Co. KG in South Westphalia is a leader in the foundry industry and specializes in series and custom-made cast parts made of aluminium alloys. The family-run company with 650 employees supplies its customers worldwide with high-quality raw castings as well as machined sand and permanent mold castings. The molds are made of bentonite-bonded mold material based on quartz sand.

A considerable amount of fine quartz dust is produced when the cores are removed from the castings. During the subsequent fettling and grinding of the cast parts, explosive aluminum dust is also released, which requires a technical solution in accordance with the statutory explosion protection regulations (ATEX).

To meet these challenges and open up a new work area with two separate work booths, the foundry was looking for a safe extraction solution for large quantities of quartz dust and explosive aluminum dusts. The extraction systems should be placed indoors as close as possible to the point of origin, the work cabins.

INDUSTRY

Foundry

Metal processing

PROCESSES

Decoring of cast parts

Grinding & fettling of aluminum cast components

MEDIA

Quartz dusts

Aluminum dusts

(explosive & flammable)

Requirement:

- New work area with two sanding cabins

- Two extraction systems for different dusts:

1. quartz dust

2. aluminum dust (explosive) - Indoor installation near the cabins

- Automatic discharge

- Energy efficiency

- Robust, high-quality construction

- Low effort for filter change & maintenance

Our extraction solution:

2 soundproof work cabins

Two soundproofed sanding cabins with side hoods and work tables for dust collection were installed for the new work area. One cabin is used to remove the castings from the quartz sand molds, while the aluminum castings are ground and cleaned in the other cabin.

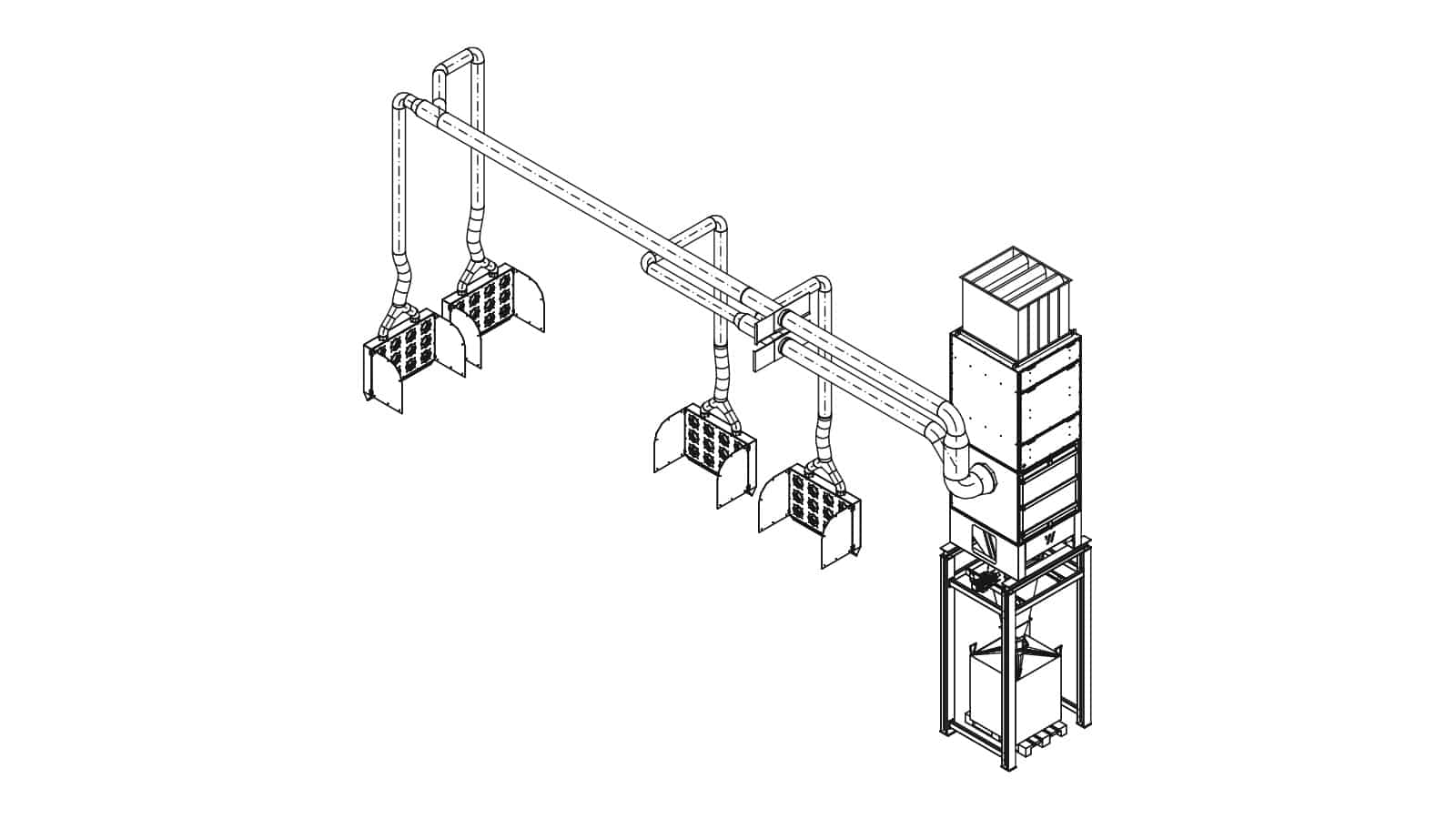

ATEX deduster for aluminum dust

An Atex dust extractor with 30 kW and 31,000 m³/h output reliably extracts the aluminum dust. 6 filter cartridges with 300m² filter surface and HEPA H14 filter for fine dust clean the cabin air. A pre-separator protects the filters from sparks and coarse dust and increases the filter service life.

Deduster for quartz dust

The deduster for the quartz dust has 11 kW and max. 15,000 m³/h extraction capacity. The dust is bound by 6 filter cartridges with 150m² and a second filter stage with HEPA H14 filters. Rotary valves transport the dust into BigBags for disposal.

Intelligent control: LOGO!

The filtered dust automatically lands in a BigBag via a rotary valve . About a SIEMENS LOGO! 8, the filling levels of the BigBags, filter performance and automatic filter cleaning are monitored and controlled.

The fire protection measures are also activated via the control system as required. These include temperature sensors, radio sensors, warning alarms and extinguishing agent containers.

Result:

✓ ATEX dry extraction

Less piping and shorter air flows make the systems more cost-effective and energy-efficient. They can be flexibly rearranged in the hall during restructuring.

✓ Security

The statutory ATEX directives, workplace regulations and occupational health and safety are complied with. Fires and explosions are prevented by a multi-level safety concept.

✓ Automatic operation

The big bags with fill level monitoring and automatic filter cleaning and monitoring make the systems very low-maintenance and user-friendly. This saves time and money.

Only one manufacturer was able to implement ATEX dedusting indoors!

„For the extraction of...

Dr. Georg Wilhelm Dieckhues

OHM & HÄNER

We support our customers from A to Z: personal advice, technical design, planning of the pipe system, production, installation, piping, commissioning, maintenance and after-sales.

TECHNICAL DATA

- Work areas: 2 soundproofed work cabins

- Systems:

1. ATEX dust extractor series P 6000, 30 kW

2. P 4000 series dust extractor, 11 kW - Max. Air volume:

1. 31,000 m³/h

2. 15,000 m³/h - Air flow: Recirculated air

- Installation: Indoor area

- Filter: Cartridge filter, HEPA H14 filter

- Control system: Siemens LOGO! 8 with frequency inverter and much more.

- Acquisition: Side hoods & extraction tables

- Discharge: rotary valves with BigBags

- Pipe system: 97 m longitudinal seam pipe

ADVANTAGES AT A GLANCE

- Individual, economical extraction solution with pipe system

- ATEX dry extraction in indoor areas

- High extraction power

- Low energy consumption

- Low operating costs

- Planning and installation directly from the manufacturer

ABSAUGWERK offers first-class extraction solutions for the manufacturing industry that protect people, machines and the environment. We are proud to make workplaces safer and cleaner with our systems. In this way, we actively contribute to the protection of employees, extend the service life of machinery and reduce the environmental impact.