QUADRUS METALLTECHNIK

Wet separator for aluminum dustQUADRUS METALLTECHNIK

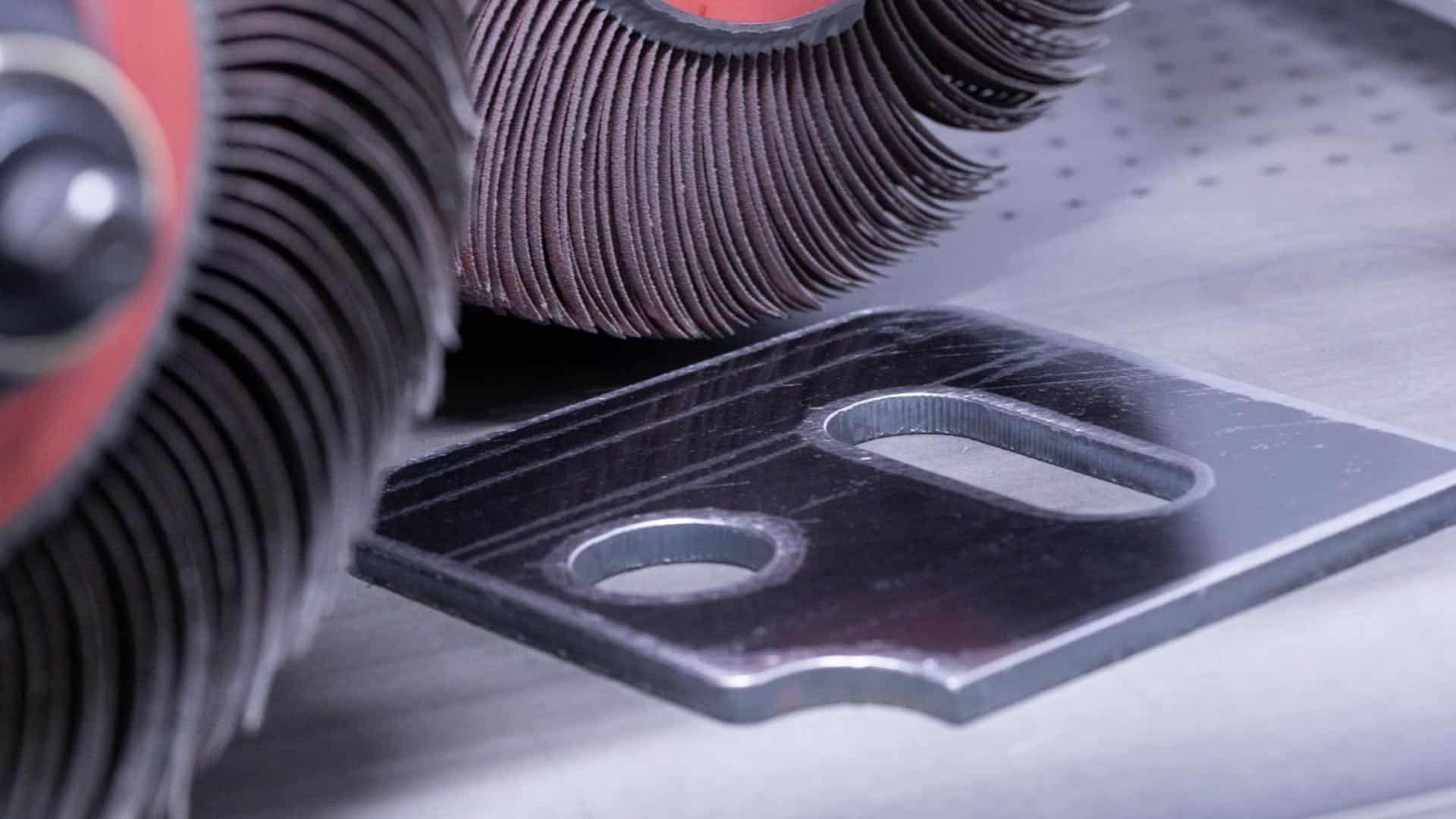

Wet separator for aluminum dustThe family-owned company Quadrus Metalltechnik GmbH, based in Schmidgaden, is an expert in laser technology, forming technology, welding technology and assembly. Up to 1,100 tons of steel, stainless steel and aluminium are processed there every month. Particular emphasis is placed on quality, precision and optimum verticalization processes in order to achieve perfect results.

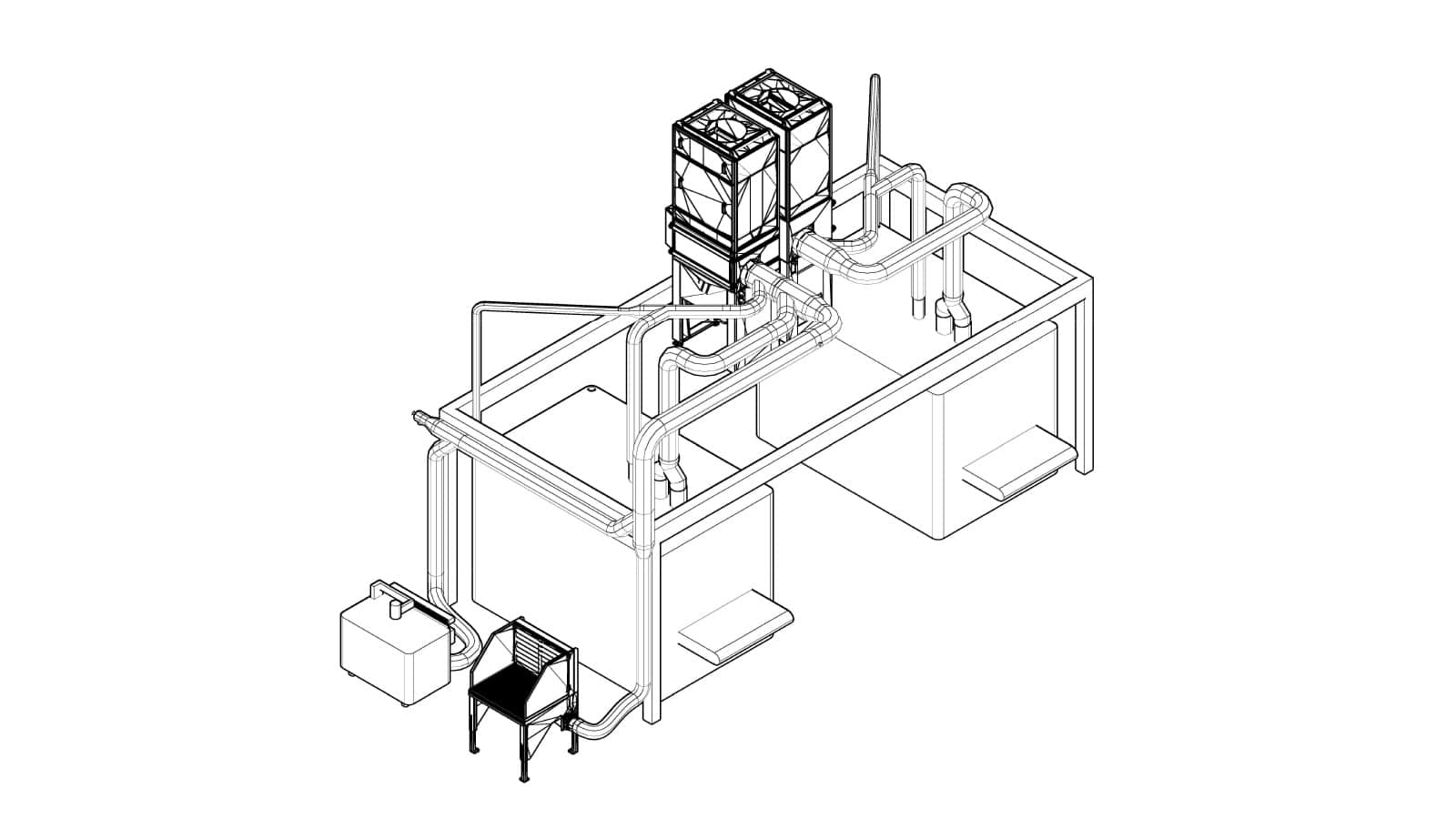

To ensure safety in accordance with occupational health and safety regulations and to protect workpieces and machines, hazardous and explosive dusts generated during welding, laser cutting, forming and deburring processes must be reliably extracted. Our special ATEX wet separators were used for the extraction of two Timesavers deburring machines, one for aluminum and stainless steel parts and another for the separate processing of steel.

In addition, our extraction table enables the production of individual parts and complex assemblies according to individual customer requirements.

INDUSTRY

metalworking

PROCESSES

Deburring

Sanding

Edge rounding

MEDIA

Stainless steel dusts

(carcinogenic)

Aluminum dusts

(explosive)

Requirement:

- Extraction from 2 deburring machines

- Can be switched on for 2 manual workstations

- Material mix of stainless steel, steel and aluminum

- Placement of the systems on the platform

- Easy emptying of the discharge

- Compliance with applicable workplace regulations

- Low maintenance

- Low operating costs

Our extraction solution:

2 systems for 4 work areas

The two ATEX wet separators extract the dust from the two deburring machines and filter it through several filter stages. Two work tables for manual work can be activated via the control system if required. The cleaned air is fed back into the production hall (recirculation mode), while the separated dust is disposed of as sludge via a rollable container.

Work safely and healthily

The combustible aluminum dusts can easily be ignited by a spark and lead to dangerous explosions. Wet separators and pipe systems must comply with statutory ATEX regulations to ensure safe operation.

The carcinogenic stainless steel dust requires a special HEPA H14 filter to prevent it from getting into the air that employees breathe.

Flexibility and low operating costs

For small batch sizes, the customer uses a manual grinder and our WT series extraction table. The manual workstations enable efficient and precise deburring and edge processing for custom-made products. The flexible use of the systems for 4 work areas saves operating costs and space in production.

Result:

✓ Clean work area

The two wet separators clean the process air and are used optimally for 4 work areas.

✓ Safe operation

Compliance with the applicable ATEX and occupational safety regulations ensures safe operation and employee protection.

✓ Custom-made products

Through our development department, we plan energy-efficient complete solutions incl. pipe system and technically implement individual customer requirements.

Very high extraction performance and good service!

»ABSAUGWERK is characterized by very high extraction...

Hans Maier

QUADRUS Metalltechnik GmbH

We support our customers from A to Z: personal advice, technical design, planning of the pipe system, production, installation, piping, commissioning, maintenance and after-sales.

TECHNICAL DATA

- Systems: 2 wet separators series W 3000,

Extraction table series WT - Performance: 11 kW

- Max. Air volume: 10,000 m³/h

- Air flow: Recirculated air

- Installation: Indoor area

- Filter: Stainless steel mesh, HEPA H14 filter

- Control system: Siemens LOGO! 8

- Detection: Via pipe system on machines & tables

- Discharge: ball valve, sludge tank 60 L

- Pipe system: 44 m longitudinal seam pipe

- ATEX execution

ADVANTAGES AT A GLANCE

- Individual concept 2 systems – 4 work areas

- Cost-effective and economical

- High extraction power

- Low energy and water consumption

- Low operating costs

- Washable stainless steel mesh filters

- Development and assembly directly from the manufacturer

ABSAUGWERK offers first-class extraction solutions for the manufacturing industry that protect people, machines and the environment. We are proud to make workplaces safer and cleaner with our systems. In this way, we actively contribute to the protection of employees, extend the service life of machinery and reduce the environmental impact.