D. La Porte Söhne

Oil mist separator for the foundryD. La Porte Söhne

Oil mist separator for the foundry

D. La Porte Söhne GmbH has been producing high-precision locks and fittings for the commercial vehicle and automotive industry for almost 160 years. In the die casting foundry, 7 casting machines work simultaneously in 2-shift operation. To prevent the parts from sticking to the tools, they are wetted with a fine spray of cooling lubricant or separating oil, which releases fine aerosols and oil mist. These remain in the hall air until they are deposited as a fine oil film on floors, walls and surfaces.

DLP had previously installed an extraction system with electrostatic filter in recirculation mode, but was dissatisfied with the separation performance and air quality. The filters quickly became clogged and required frequent cleaning. This had to be prevented during the technical planning of the new solution.

INDUSTRY

Foundry

Automotive

PROCESSES

Die casting, spraying of cooling lubricants and separating oil

MEDIA

Oil vapor

Aerosols

Requirement:

- One extraction system for 4 casting machines

- Simultaneous use of the machines

- Reduction of heat generation by die casting machines

- Continuous fresh air supply

- Compliance with applicable workplace regulations

- Long filter service lifetime

- Minimal cleaning effort

Our extraction solution:

Clean air in 3 stages

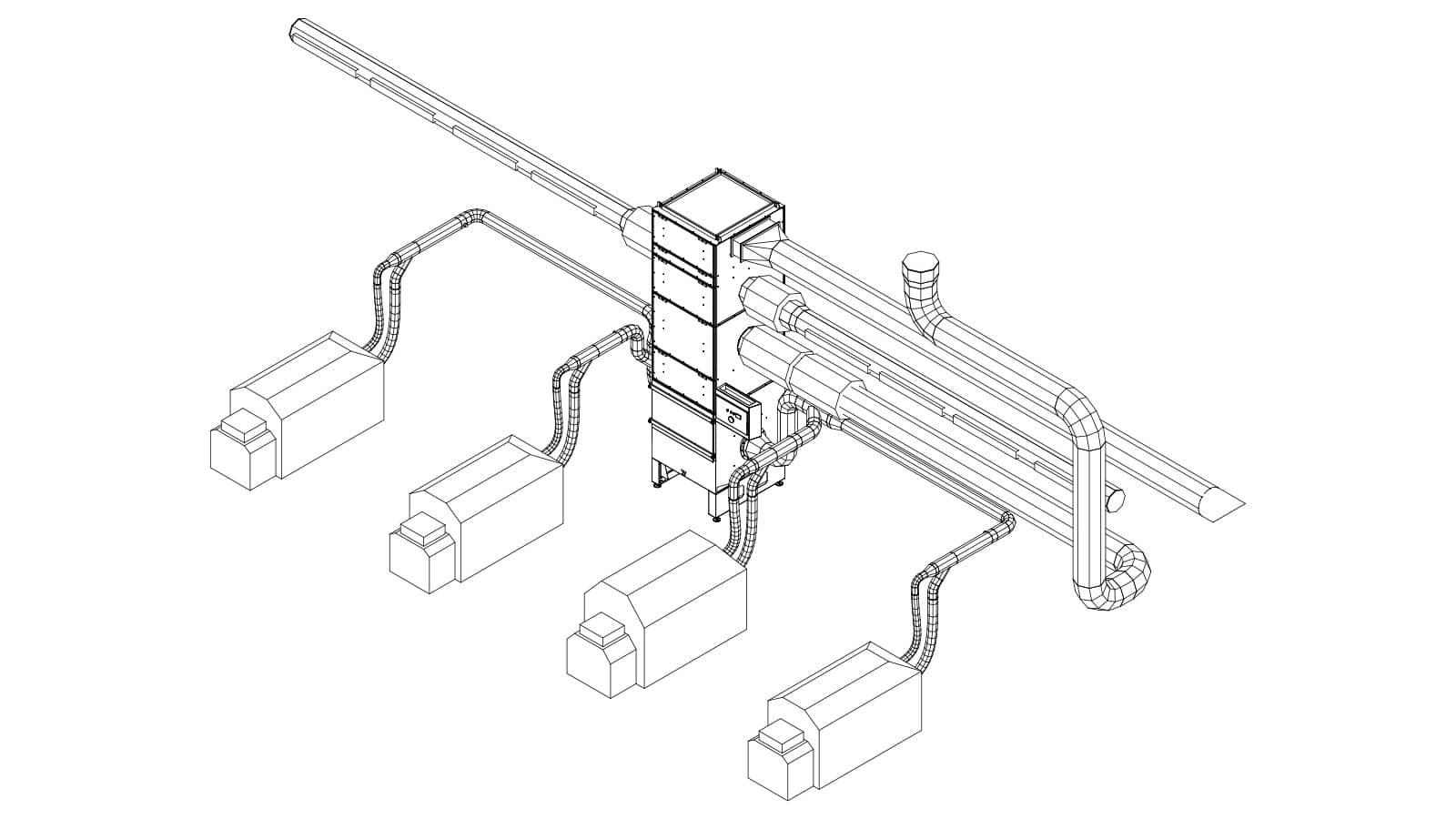

The E Series 4000 oil mist separator with 7,200 m³/h captures fine oil particles and aerosols via eight slotted hoods. The oily air passes through two filter stages made of a special stainless steel mesh and a final cleaning process using four cassette filters.

2-in-1 solution

To improve the air quality and cool the hall at the same time, a fresh air box was integrated into the extraction system – a space- and cost-saving 2-in-1 solution developed by our technical manager Martin Prokisch.

Recycling of lubricants

The cleaned process air is discharged to the outside, while the separated lubricants can be collected in the discharge container and reused.

Result:

✓ Air pollution control & resource conservation

The fine oil particles are not only removed from the hall air, but also from floors and surfaces. Lubricants are collected and returned to the machines.

✓ Space and cost savings

The oil mist separator has sufficient power for all 4 machines, even when used simultaneously. The integrated fresh air module combines all functions in just one system.

✓ 1 year without filter cleaning

Conclusion after one year of operation: metal mesh filter untouched, cassette filter as good as new. Filter performance only decreased by approx. 2%.

The two are worlds apart and the BG was also delighted!

»There is a...

Joachim Pirdzuns

D. La Porte Söhne GmbH

We support our customers from A to Z: personal advice, technical design, planning of the pipe system, production, installation, piping, commissioning, maintenance and after-sales.

TECHNICAL DATA

- System: E 4000 series oil mist separator

- Performance: 11 kW

- Max. Air volume: 15,000 m³/h

- Operating point: 5,800-7,200 m³/h

- Air flow: Recirculated air

- Installation: Indoor area

- Filter: metal mesh filter incl. Monitoring, cassette filter (category E11)

- Control system: Siemens LOGO! 8 with frequency inverter

- Detection: Slotted hoods

- Discharge: ball valve with siphon

- Pipe system: 38 m steel pipe with shelf, 33 m spiral duct

- Integriertated fresh air unit

ADVANTAGES AT A GLANCE

- 2-in-1 solution: extraction system and fresh air box

- Space-saving, cost- and energy-efficient

- Robust, easy-to-clean knitted metal filters

- Minimal maintenance and cleaning effort

- Long life cassette filters

- Direct extraction by means of slotted hoods

- Low operating costs and quiet operation

- Low resistance in the pipe system and the installation

- Development and assembly directly from the manufacturer

ABSAUGWERK offers first-class extraction solutions for the manufacturing industry that protect people, machines and the environment. We are proud to make workplaces safer and cleaner with our systems. In this way, we actively contribute to the protection of employees, extend the service life of machinery and reduce the environmental impact.